HSE Induction for Concrete

Understanding HSE Induction for Concrete

Every construction site presents unique hazards. Therefore, a proper HSE induction for concrete finisher personnel is non-negotiable. This process introduces workers to site-specific health, safety, and environmental protocols.

Specifically, it addresses the dangers of concrete work. Furthermore, it ensures every team member understands their role in maintaining a safe workplace. This foundational training is the first line of defense against accidents.

HSE Induction for Concrete Benefits

A thorough safety induction offers immense advantages. First, it significantly reduces workplace incidents and near-misses. Consequently, this leads to lower insurance premiums and fewer project delays.

Additionally, it fosters a strong safety culture among the crew. Workers feel valued and protected. Moreover, it ensures compliance with international standards from the International Labour Organization guidelines.

How HSE Induction for Concrete Works

The induction process typically begins on a worker’s first day. It involves both classroom-style learning and practical, on-site demonstrations. Trainers cover essential topics like material handling and equipment operation.

For example, they demonstrate proper personal protective equipment (PPE) use. They also explain emergency procedures and site evacuation routes. This comprehensive approach ensures no critical safety aspect is overlooked.

Best HSE Induction for Concrete Practices

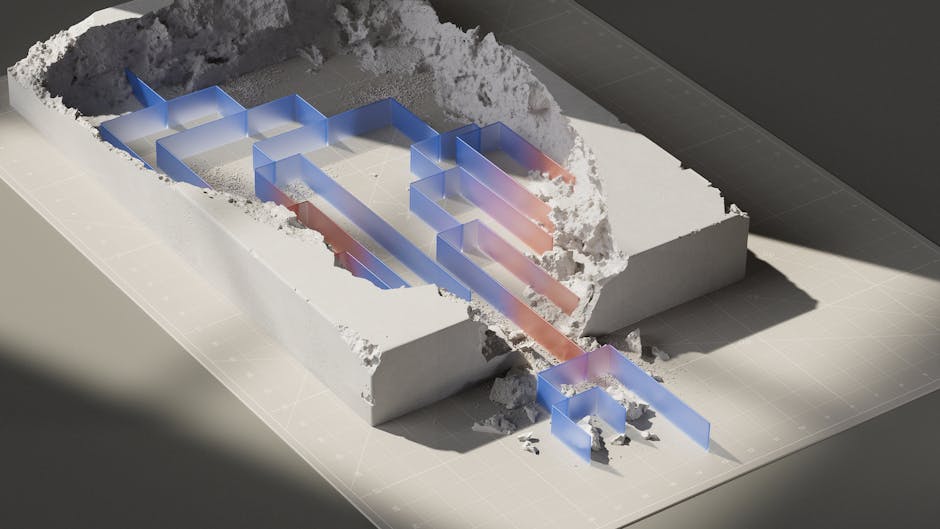

Effective safety training follows several key principles. First, it must be engaging and easy to understand. Using visual aids and real-life examples greatly improves knowledge retention.

Additionally, the content should be tailored specifically for concrete finishing tasks. This includes discussing silica dust exposure and wet concrete hazards. Regular refresher courses are also a best practice endorsed by the World Health Organization workplace standards.

HSE Induction for Concrete Implementation

Implementing a robust safety program requires careful planning. Site managers must first identify all potential risks. Next, they develop training modules that address these specific hazards.

Documentation is a critical part of this phase. Therefore, every worker’s participation must be recorded. Furthermore, assessments should verify their understanding of the material. For support, consider our professional resources.

Advanced HSE Induction for Concrete Strategies

Modern safety training leverages technology for better outcomes. Virtual reality (VR) simulations can recreate hazardous scenarios without any real-world risk. This allows workers to practice their response in a controlled environment.

Moreover, digital tracking systems can monitor training compliance and skill retention. These advanced tools align with global trends noted in World Bank economic reports. They represent the future of construction safety.

HSE Induction for Concrete Success Tips

Consistent communication is vital for program success. Supervisors should reinforce safety messages daily during toolbox talks. Additionally, they must lead by example by always following protocols themselves.

Recognizing and rewarding safe behavior also motivates the team. Conversely, any safety violations must be addressed immediately and constructively. This balanced approach maintains high standards.

Future of HSE Induction for Concrete

The landscape of construction safety is continuously evolving. Emerging technologies like wearable sensors and AI are set to revolutionize training. These tools can provide real-time feedback to workers.

Furthermore, global standards are becoming more harmonized. Regulations in regions like the UAE, guided by the UAE government employment regulations, are setting new benchmarks. The industry is moving towards a zero-harm philosophy.

Frequently Asked Questions

What is the main goal of a safety induction?

The primary goal is to ensure every worker understands site-specific hazards and safety procedures. This foundational knowledge prevents accidents and promotes a safe working environment for all personnel.

How long does a typical induction take?

A comprehensive session usually lasts between two to four hours. However, the duration can vary based on site complexity and the specific risks associated with the concrete finishing tasks being performed.

Is this training legally required?

Yes, most countries mandate basic safety training under occupational health and safety laws. Compliance is also often required by project clients and insurance providers to mitigate liability.

What topics are covered for concrete finishers?

Key topics include silica dust management, chemical handling, tool safety, ergonomics, and fall protection. It also covers first aid procedures and emergency response plans specific to the worksite.

How often should refresher training occur?

Annual refreshers are a common industry standard. However, immediate additional training is required after any incident or when new equipment or significant procedural changes are introduced on site.

Who is responsible for providing the induction?

The principal contractor or site manager holds the primary responsibility. They must ensure all workers, including subcontractors, receive appropriate training before starting work, as per U.S. Department of Commerce trade information best practices.

Conclusion

A robust HSE induction for concrete finisher teams is a critical investment. It protects your most valuable asset: your people. Furthermore, it safeguards project timelines and financial viability.

The construction industry’s commitment to safety is stronger than ever. By implementing a thorough and engaging program, you build a culture of care and professionalism. This commitment ensures everyone returns home safely each day.

Do not leave safety to chance. Protect your team and your project. Get expert consultation today to develop your customized safety plan. You can also schedule an appointment with our specialists for a comprehensive site assessment.