Are you ready to transform your facility management operations from reactive to predictive? Furthermore, the GCC’s rapidly evolving built environment demands smarter, data-driven solutions. Consequently, 3D mapping digital twin FM planning represents a revolutionary leap forward. This approach creates dynamic virtual models for superior space and asset management. Therefore, embracing this technology is no longer optional for competitive advantage.

Facility management in the Gulf region faces unique challenges. Extreme climates, ambitious mega-projects, and stringent sustainability goals require innovative tools. Moreover, digital twins provide a centralized, interactive view of your entire physical asset portfolio. This enables proactive maintenance, efficient space utilization, and cost optimization. Additionally, integrating this technology supports compliance with regional smart city initiatives.

At Allianze HR Consultancy, we understand that technological adoption requires skilled talent. Furthermore, our 5+ years of GCC expertise supports clients from 50+ countries. We’ve successfully placed 10,000+ professionals across UAE, Saudi Arabia, Qatar, and Kuwait. Moreover, our Ministry of External Affairs (India) RA license ensures compliance in all recruitment activities. Therefore, contact our recruitment specialists to build the team that will implement your digital transformation.

Understanding Modern Facility Management Technology

Facility management has evolved far beyond basic maintenance. Today, it encompasses strategic asset lifecycle management and operational intelligence. Furthermore, technologies like IoT sensors, BIM (Building Information Modeling), and cloud platforms are converging. This convergence creates powerful data ecosystems for decision-makers. Consequently, understanding this landscape is the first step toward digital transformation.

In the GCC, several factors drive technology adoption. Firstly, vision documents like Saudi Vision 2030 and UAE Vision 2021 emphasize smart infrastructure. Secondly, large-scale assets like NEOM and Expo City Dubai require next-generation management tools. Thirdly, economic diversification pushes for operational excellence across all sectors. Therefore, facility managers must leverage data to demonstrate value and ensure longevity.

- Integration of IoT for real-time equipment monitoring.

- Use of BIM data for accurate as-built digital models.

- Cloud-based platforms for centralized data access.

- AI and analytics for predictive maintenance scheduling.

- Mobile solutions for technician workflow management.

Transitioning to a data-centric model requires careful planning. Moreover, it demands a workforce skilled in both FM principles and new technologies. Subsequently, strategic recruitment becomes a critical success factor. Partnering with experts who understand these dual requirements ensures a smoother implementation.

3D Mapping Digital Twin FM Planning Strategic Overview

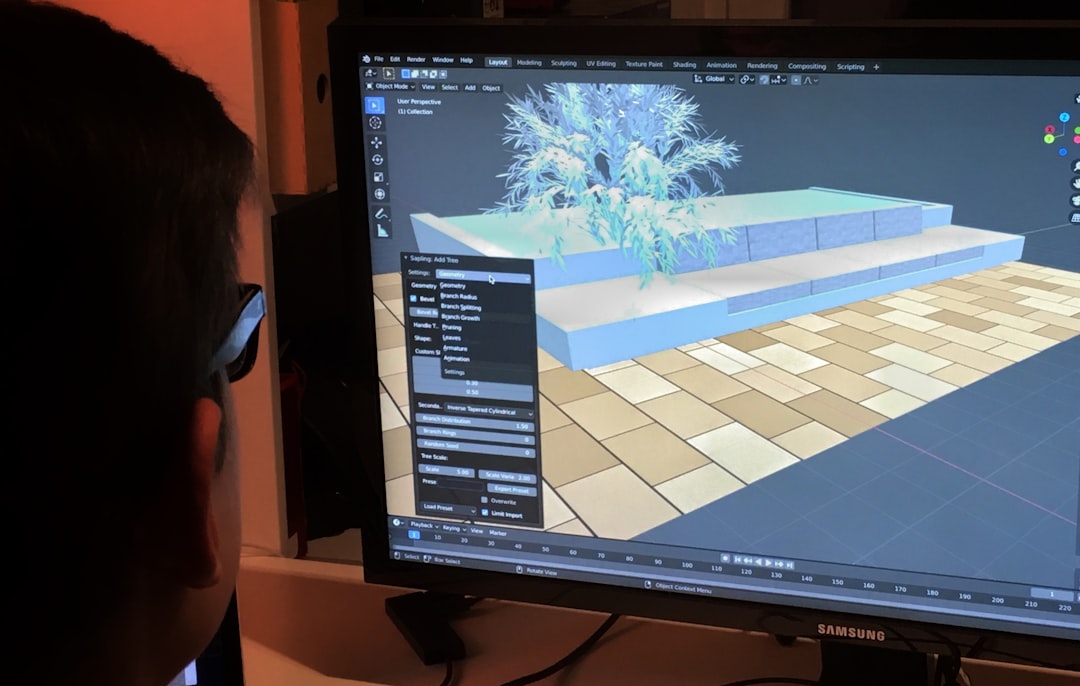

A digital twin is a dynamic virtual replica of a physical facility. It syncs with real-world data through sensors and systems. Consequently, 3D mapping digital twin FM planning enables unprecedented oversight and control. This strategic overview connects spatial data with live operational information. Therefore, it transforms how facilities are managed, maintained, and optimized.

The core value lies in the bidirectional data flow. Changes in the physical world update the digital model instantly. Conversely, simulations run in the digital twin can inform physical actions. For example, you can test a new office layout virtually before construction. Additionally, you can model energy flow to identify conservation opportunities. This capability is invaluable for complex GCC facilities.

- Centralized visualization of all assets in their spatial context.

- Live tracking of environmental conditions like temperature and humidity.

- Simulation of emergency scenarios for improved safety planning.

- Integration with CAFM (Computer-Aided Facility Management) software.

- Historical data analysis for lifecycle cost forecasting.

Implementing this strategy requires cross-functional collaboration. Furthermore, it bridges the gap between IT, operations, and finance departments. Moreover, success depends on clear objectives aligned with business goals. A phased approach often works best, starting with a pilot area. This allows for learning and adjustment before full-scale deployment.

Legal Framework and GCC Compliance Standards

Deploying advanced technologies must align with regional regulations. GCC countries have specific data laws, building codes, and cybersecurity mandates. For instance, the UAE’s Data Law and Saudi’s PDPL govern data collection and usage. Therefore, ensuring your digital twin complies is non-negotiable. Additionally, International Labour Organization standards inform workplace safety protocols integrated into models.

Building and construction standards are particularly rigorous. Authorities like Dubai Municipality and Saudi Building Code have strict requirements. Digital twins must accurately reflect approved structural and MEP (Mechanical, Electrical, Plumbing) designs. Moreover, sustainability regulations, such as Abu Dhabi’s Estidama, require performance tracking. Consequently, your virtual model becomes a tool for demonstrating compliance.

- Adherence to UAE Fire and Life Safety Code.

- Compliance with UAE green building regulations.

- Cybersecurity measures per National Electronic Security Authority guidelines.

- Data privacy alignment with the Gulf Data Protection Law.

- Integration with Saudi Ministry of Labor occupational health standards.

Navigating this landscape requires expert knowledge. Furthermore, your FM team must understand both the technology and the regulatory environment. Therefore, recruitment should prioritize candidates with GCC-specific experience. This ensures your digital initiative progresses without legal obstacles.

3D Mapping Digital Twin FM Planning Best Practices

Successful implementation hinges on established best practices. Firstly, begin with a clear definition of business objectives and KPIs. What problems are you solving? Secondly, ensure data quality and standardization from the outset. Garbage in leads to garbage out, even in a sophisticated digital twin. Thirdly, foster a culture of collaboration between all stakeholders. Consequently, these steps lay a strong foundation for your project.

Data integration is a critical phase. Your digital twin must pull information from various existing systems. These include BIM, CMMS, IoT platforms, and energy management systems. Moreover, establishing a single source of truth prevents conflicts and confusion. Additionally, consider scalability from day one. The model should accommodate future expansion or portfolio growth.

- Start with a high-value, manageable asset for pilot testing.

- Implement robust change management to support user adoption.

- Establish clear data governance and ownership protocols.

- Prioritize user-friendly visualization interfaces for non-technical staff.

- Schedule regular model updates to reflect physical renovations.

Furthermore, training is indispensable. Your facility management team must know how to use the twin effectively. Moreover, they should interpret its insights to drive actions. Therefore, budget for comprehensive training programs during rollout. This investment maximizes your technology return. Ultimately, the twin should become a daily decision-support tool, not a static archive.

Documentation and Technical Processing Steps

The creation of a digital twin is a meticulous process. It begins with comprehensive data acquisition. This involves 3D laser scanning, photogrammetry, and extracting data from existing BIM models. Subsequently, this raw data is processed and integrated into a unified platform. Moreover, each asset within the model is tagged with metadata. This includes manufacturer details, installation dates, warranty information, and maintenance history.

Next, the integration of live data streams is configured. IoT sensors for monitoring HVAC, lighting, and occupancy are connected. Additionally, work order systems and energy meters are linked to the digital replica. Consequently, the twin becomes a living system. Furthermore, establishing access protocols and user permissions is crucial for security. Different staff members need different levels of interaction with the model.

- Conduct a detailed audit of existing assets and systems.

- Capture precise 3D spatial data using LiDAR or drone surveys.

- Clean and classify all data before integration.

- Develop a standardized naming convention for all assets.

- Create user manuals and standard operating procedures.

This technical process requires a specialized skill set. It blends surveying, data science, software engineering, and FM knowledge. Therefore, assembling the right project team is paramount. Alternatively, partnering with experienced technology providers can accelerate deployment. In either case, detailed documentation at each step ensures project continuity and knowledge retention.

3D Mapping Digital Twin FM Planning Implementation Timeline

A realistic timeline is vital for managing expectations and resources. Typically, a full-scale implementation spans 6 to 18 months. The duration depends on facility complexity, data availability, and project scope. Furthermore, the process is iterative, not linear. Consequently, planning for phases and feedback loops is essential. A common approach includes discovery, design, development, deployment, and optimization stages.

The discovery phase involves stakeholder interviews and goal setting. This may take 4-6 weeks. Subsequently, the design phase outlines the technical architecture and data strategy. Meanwhile, the development phase builds the core digital twin platform. This is often the longest stage, potentially lasting 6-9 months. Finally, deployment involves user training and go-live, followed by continuous optimization.

- Months 1-2: Project kick-off, stakeholder alignment, and data audit.

- Months 3-5: Data capture (scanning), platform selection, and model development.

- Months 6-9: System integration, testing, and initial user training.

- Months 10-12: Phased rollout, feedback collection, and process refinement.

- Ongoing: Continuous improvement, model updates, and capability expansion.

Moreover, securing skilled personnel can impact this timeline significantly. Delays in hiring the necessary BIM specialists, data analysts, or IoT engineers can stall progress. Therefore, proactive talent acquisition is a critical path item. Partnering with a recruitment firm that understands these niche roles ensures your project stays on schedule.

Common Challenges and Strategic Solutions

Despite its benefits, digital twin adoption faces several hurdles. A primary challenge is data silos and poor data quality in legacy systems. Furthermore, high initial investment costs can deter decision-makers. Additionally, organizational resistance to change is a common human factor. Moreover, a shortage of skilled professionals in the GCC market slows implementation. Therefore, anticipating these challenges allows for proactive mitigation.

Strategic solutions exist for each barrier. For data issues, begin with a thorough cleansing and migration project. For cost concerns, build a strong business case focused on ROI through energy savings and reduced downtime. To overcome resistance, involve end-users early and demonstrate quick wins. Finally, for the skills gap, develop a mix of hiring, training, and strategic partnership. World Bank labor market insights highlight the global competition for tech talent.

- Challenge: Legacy system integration. Solution: Use middleware and open API standards.

- Challenge: Cybersecurity risks. Solution: Implement zero-trust architecture and regular audits.

- Challenge: Keeping the model updated. Solution: Automate data feeds and assign update responsibilities.

- Challenge: Demonstrating value. Solution: Define and track specific KPIs from day one.

- Challenge: Scalability. Solution: Design with a modular, cloud-native architecture.

Understanding these challenges is not a reason for hesitation. Conversely, it is a blueprint for careful planning. Moreover, many early adopters in the GCC have paved the way. Learning from their experiences reduces risk. Consequently, a well-planned initiative can navigate these obstacles successfully.

Expert Recommendations for FM Transformation Success

To ensure long-term success, follow these expert recommendations. First, secure executive sponsorship and align the project with corporate strategy. This ensures sustained funding and organizational priority. Second, start with a clear, limited use case that delivers tangible value. For example, optimizing meeting room utilization or reducing energy consumption in a specific wing. Third, treat data as your most valuable asset. Invest in its quality, governance, and security.

Furthermore, build a cross-functional team with both FM domain experts and digital skills. This blend is crucial for translating operational needs into technical solutions. Moreover, choose technology partners carefully. Look for providers with proven experience in the GCC region and your specific sector. Additionally, plan for continuous evolution. The digital twin is not a one-time project but a platform that should grow with your needs.

- Develop a multi-year roadmap that links technology to business outcomes.

- Foster partnerships with local universities to build a talent pipeline.

- Leverage International Facility Management Association resources for global best practices.

- Integrate wellbeing standards per World Health Organization indoor air quality guidelines.

- Regularly benchmark performance against regional and global standards.

Finally, view this transformation as a journey. Celebrate milestones and learn from setbacks. Consequently, your organization will build digital maturity over time. This maturity translates directly to operational resilience, cost efficiency, and enhanced asset value. The future of facility management is digital, and the time to begin is now.

Frequently Asked Questions About 3D Mapping Digital Twin FM Planning

What is the primary benefit of 3D mapping digital twin FM planning?

The primary benefit is proactive, data-driven decision-making. Furthermore, it provides a single source of truth for all facility data. Consequently, this improves maintenance efficiency, space utilization, and long-term capital planning. Therefore, it transforms FM from a cost center to a value driver.

What is the typical cost range for implementing a facility digital twin?

Costs vary widely based on facility size and complexity. Factors include data capture scope, software licensing, and integration needs. Moreover, a pilot project for a single building may start at a modest investment. Therefore, schedule a consultation appointment for a tailored assessment.

How does a digital twin support sustainability goals in the GCC?

It enables precise monitoring and optimization of energy and water consumption. Additionally, you can simulate the impact of retrofit projects before investment. Consequently, it directly supports compliance with green building standards like LEED and Estidama. Moreover, it aids in reporting for ESG (Environmental, Social, and Governance) frameworks.

What skills are needed to manage a digital twin platform?

A blend of FM knowledge, data analysis, and basic IT skills is ideal. Specifically, skills in BIM, IoT data interpretation, and CAFM software are valuable. Furthermore, strategic thinking to translate data into action is crucial. Therefore, recruitment often targets hybrid professionals or builds teams with complementary skills.

Can digital twins be applied to existing older buildings?

Absolutely. Laser scanning and photogrammetry can accurately capture as-built conditions. Furthermore, the process often reveals hidden inefficiencies in older structures. Consequently, it is a powerful tool for retrofit planning and legacy asset management. The key is accurate data capture, regardless of building age.

How does Allianze HR support digital transformation projects?

We recruit the specialized talent required for technology implementation and management. Our network includes BIM