Onboarding best practices

Understanding Onboarding best practices

Effective employee integration is crucial for manufacturing success. This is especially true in Saudi Arabia’s evolving industrial sector. However, a structured approach ensures new hires become productive quickly.

Furthermore, a well-defined process reduces early turnover. It also builds a strong foundation for long-term employee engagement. Additionally, it aligns worker expectations with company culture and safety standards.

Specifically, onboarding best practices for assembly workers in Saudi Arabia require cultural sensitivity. They must also comply with local labor laws known as the Saudi Labor Law. This creates a unique and rewarding implementation challenge.

Onboarding best practices Benefits

A strategic onboarding program delivers significant organizational advantages. Therefore, companies investing in this area see measurable returns.

First, it dramatically accelerates time-to-competence for new assembly staff. Consequently, production lines maintain quality and efficiency standards faster. This protects your bottom line from new hire lag time.

Moreover, a positive initial experience fosters strong loyalty. It demonstrates the company’s commitment to its workforce. This is a powerful tool for retention in a competitive market.

Finally, it ensures consistent understanding of critical safety protocols. This minimizes workplace accidents and associated costs. For more global context, see the International Labour Organization guidelines.

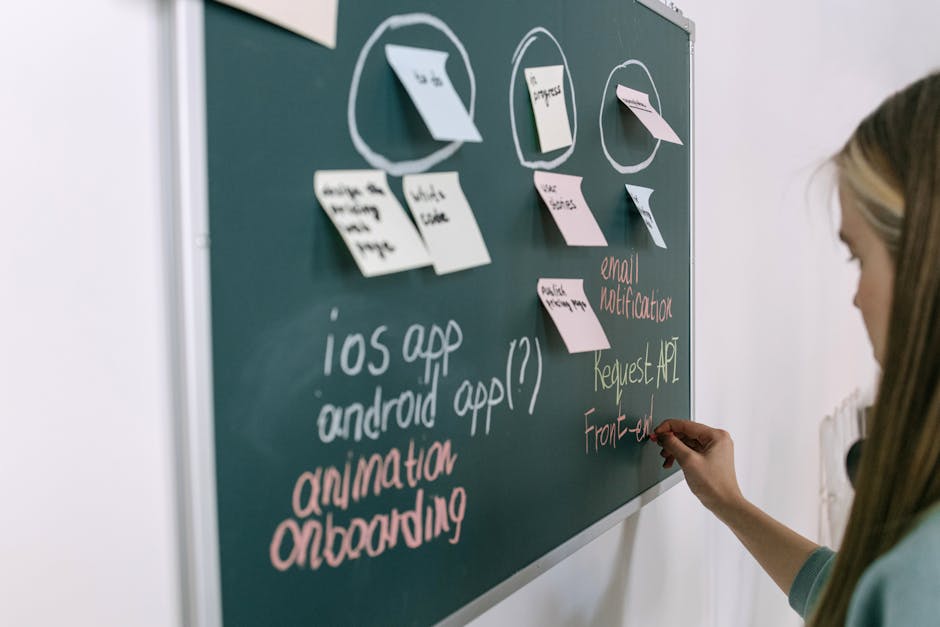

How Onboarding best practices Works

A successful new hire integration process is a multi-stage journey. It begins before the employee’s first day and extends for months.

Typically, the pre-boarding phase involves completing administrative paperwork. This includes Iqama and GOSI registration in the Saudi context. Next, the first week focuses on orientation and basic training.

Subsequent weeks blend hands-on practice with mentorship. Furthermore, regular check-ins assess progress and address concerns. This structured support system is the core of how it functions.

Specifically, the process translates company knowledge into practical assembly line skills. It bridges the gap between hiring and full, independent productivity. For international trade insights, the U.S. Department of Commerce trade information is useful.

Best Onboarding best practices

Implementing a world-class integration program requires deliberate planning. Here are the most effective strategies tailored for Saudi Arabia.

First, develop a culturally adapted welcome program. This should include basic Arabic greetings and an understanding of local customs. It shows respect and facilitates smoother team integration.

Additionally, assign a seasoned colleague as a mentor or “buddy.” This provides the new worker with a go-to person for daily questions. Consequently, it reduces first-week anxiety and confusion.

Moreover, use visual work instructions and standardized work charts. These tools overcome potential language barriers on the factory floor. They ensure clarity and consistency in assembly tasks from day one.

Onboarding best practices Implementation

Turning theory into action requires a clear, phased rollout plan. Successful execution depends on coordination between HR and operations management.

Begin by creating a detailed checklist for the first month. This checklist should cover legal, technical, and social integration milestones. Therefore, nothing is overlooked during the critical initial period.

Next, conduct role-specific safety demonstrations. These must go beyond generic videos. For example, show the exact safety procedures for the specific machinery the worker will use.

Furthermore, schedule formal feedback sessions at 30, 60, and 90 days. These sessions gather insights on the process’s effectiveness from the new employee’s perspective. This data is invaluable for continuous improvement. For regional regulatory context, review the UAE government employment regulations.

Advanced Onboarding best practices Strategies

To gain a competitive edge, companies can move beyond the fundamentals. These advanced tactics deepen engagement and accelerate expertise.

Implement a gamified learning path for assembly skills. Use digital badges or small incentives for completing training modules. This makes skill acquisition more engaging and memorable.

Additionally, create a “day-in-the-life” video series. Feature high-performing current assembly workers going through their routines. This provides realistic job previews and sets clear performance expectations.

Moreover, introduce cross-training opportunities early. Allowing workers to learn adjacent roles increases operational flexibility. It also combat monotony and supports career development. For health standards, refer to the World Health Organization workplace standards.

Onboarding best practices Success Tips

Sustaining a high-quality program demands ongoing attention and resources. These tips ensure long-term success and relevance.

Always secure strong visible support from plant leadership. When managers champion the process, it signals its importance to the entire organization. This drives participation and accountability.

Continuously update training content to reflect process changes. An outdated onboarding program creates more problems than it solves. Therefore, assign a team member to own this content.

Furthermore, celebrate onboarding completions as a team achievement. Publicly recognize new workers who finish their probationary period. This builds morale and reinforces the value of the process. For broader economic data, the World Bank economic reports offer insights.

Future of Onboarding best practices

The landscape of employee integration is rapidly evolving. Technology and new workforce expectations are driving significant changes.

Augmented Reality (AR) is set to revolutionize hands-on training. New workers could use AR glasses to see digital instructions overlaid on physical equipment. This will drastically reduce errors and training time.

Additionally, data analytics will personalize the onboarding journey. Systems will identify individual learning gaps and automatically recommend targeted training modules. This makes the process more efficient and effective.

Moreover, as Saudi Arabia continues its Vision 2030 journey, emphasis on national talent development will grow. Onboarding programs will increasingly focus on integrating Saudi nationals into industrial roles. They will include stronger partnerships with technical colleges.

Frequently Asked Questions

What is the ideal length for an assembly worker onboarding program in Saudi Arabia?

The ideal program lasts 90 days. It covers initial orientation, technical skills training, and cultural integration. This period aligns with the common probationary period under Saudi labor law.

How can we overcome language barriers during the onboarding process?

Use visual aids, demonstrations, and bilingual mentors. Translate critical safety materials into the workers’ primary languages. Furthermore, basic Arabic phrases for commands and greetings are essential for supervisors.

What are the key legal documents required for onboarding in Saudi Arabia?

Key documents include the signed employment contract, Iqama (residency permit), and GOSI registration. Additionally, you need a valid passport, medical check-up results, and educational or training certificates.

Why is cultural training important in the onboarding process?

Cultural training fosters mutual respect and smooth team integration. It helps foreign workers adapt to local norms. It also prepares Saudi nationals for a multicultural workplace environment, reducing friction.

How do we measure the success of our onboarding program?

Track metrics like 90-day retention rates, time-to-proficiency, and quality audit scores for new hires. Additionally, use new employee satisfaction surveys to gather qualitative feedback on their experience.

What role do line managers play in effective onboarding?

Line managers are crucial. They set daily goals, provide immediate performance feedback, and reinforce safety culture. Their active involvement is the single biggest factor in a new worker’s successful integration.

Conclusion

Implementing robust onboarding best practices is a strategic imperative for manufacturers in Saudi Arabia. It directly impacts productivity, safety, and employee retention. A thoughtful, culturally-aware program is a significant competitive advantage.

The future will bring more technological integration and personalization. However, the core principles of clarity, support, and respect will remain timeless. Investing in your people from day one builds a resilient and skilled workforce.

Begin refining your process today. For further support, explore our professional resources. Ready to build a best-in-class program? Request an schedule appointment or get an expert consultation to assess your current onboarding strategy.