How can construction firms in the GCC ensure their power workers operate safely amidst complex high-voltage environments? Furthermore, the region’s rapid infrastructure growth demands rigorous safety protocols. Consequently, electrical safety construction site power management becomes a critical priority. This comprehensive guide addresses training and certification for low and high voltage work. Moreover, it provides actionable strategies for compliance and risk mitigation.

The construction sector across the Gulf faces unique electrical hazards. Specifically, extreme temperatures and large-scale projects increase risk factors. Additionally, diverse international workforces require standardized safety training. Therefore, understanding regional regulations proves essential for project success. Proper electrical safety protocols protect both personnel and substantial capital investments.

At Allianze HR Consultancy, we’ve successfully placed 10,000+ professionals across UAE, Saudi Arabia, Qatar, and Kuwait. Furthermore, our 5+ years of GCC expertise supports clients from 50+ countries. Moreover, our Ministry of External Affairs (India) RA license ensures compliance. Therefore, contact our recruitment specialists for expert guidance on staffing your projects with certified, safety-trained electrical personnel.

Understanding GCC Electrical Hazard Management

Construction sites in the Gulf present distinct electrical challenges. First, temporary power distribution systems are ubiquitous. These systems face damage from equipment, weather, and constant relocation. Second, multi-contractor environments create coordination gaps. Consequently, clear lockout/tagout procedures become vital. Third, cultural and language diversity among workers complicates training.

GCC national standards often reference international frameworks. For instance, the UAE follows strict guidelines aligned with international best practices. Similarly, Saudi Arabia’s Vision 2030 projects enforce enhanced safety codes. Employers must navigate these regional variations. Additionally, they must implement site-specific safety plans that address local conditions.

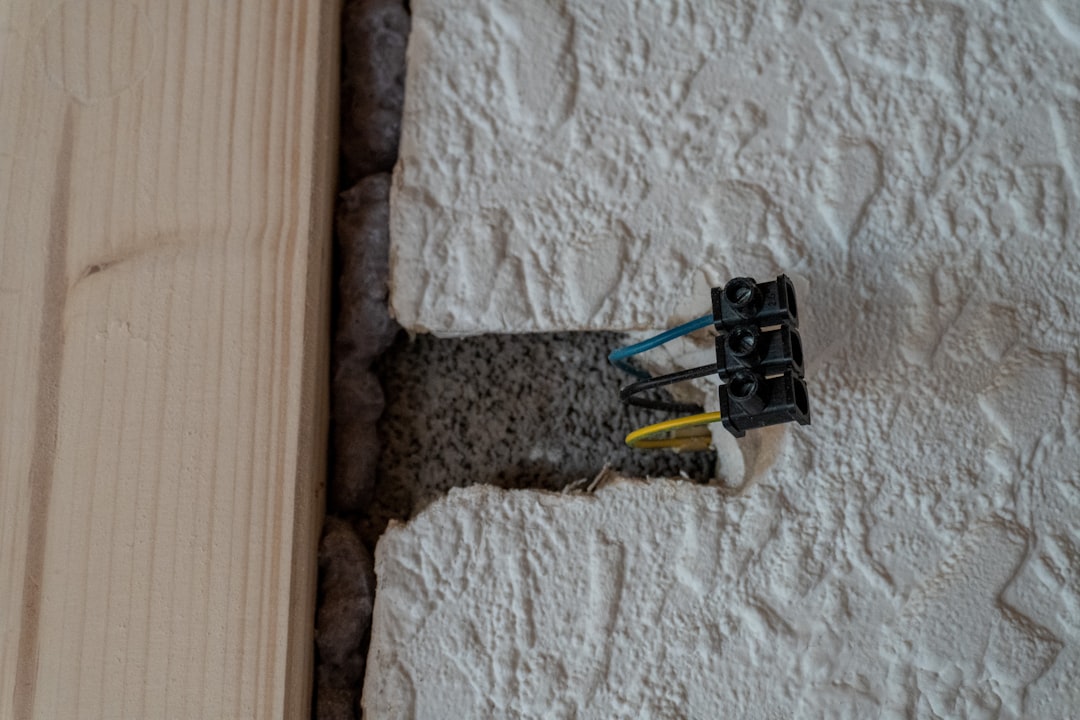

Key hazards include overhead power lines, damaged tools, and wet conditions. Furthermore, improper grounding and faulty temporary wiring cause frequent incidents. Therefore, a systematic hazard assessment is the first step. This process identifies risks unique to each project phase. Subsequently, targeted control measures can be deployed effectively.

- Temporary electrical system installation and inspection protocols.

- Multi-employer worksite communication and coordination plans.

- Extreme climate considerations for electrical equipment durability.

- Language-appropriate safety signage and training materials.

- Regular auditing of tools, cords, and personal protective equipment (PPE).

Electrical Safety Construction Site Power Strategic Overview

A strategic approach to electrical safety construction site power is non-negotiable. This begins with a top-down commitment from project leadership. Moreover, safety must be integrated into every project milestone. Financial and schedule planning must allocate resources for proper training and equipment. Consequently, this proactive stance prevents costly accidents and delays.

The strategy encompasses three core pillars: qualified personnel, robust processes, and verified equipment. First, only certified workers should perform electrical tasks. Second, documented procedures must govern all activities. Third, all tools and distribution systems require regular inspection. This holistic framework ensures comprehensive risk management across the site.

Implementation requires collaboration between HR, site management, and safety officers. HR ensures workers possess valid certifications. Site management enforces daily safety protocols. Safety officers conduct audits and incident investigations. This shared responsibility model fosters a pervasive culture of safety. Ultimately, it protects the company’s reputation and bottom line.

- Executive-level safety policy development and communication.

- Integration of electrical safety metrics into project KPIs.

- Dedicated budget for safety training, PPE, and equipment testing.

- Clear organizational chart defining electrical safety responsibilities.

- Strategic partnership with accredited training providers.

Legal Framework and Compliance Standards

GCC employers must navigate a layered legal landscape. International standards provide a foundational baseline. For example, the International Labour Organization construction safety guidelines are widely recognized. Additionally, OSHA construction industry standards offer detailed protocols for electrical work. These inform many regional regulations.

Nationally, each GCC country has its own regulatory body. The UAE’s Ministry of Human Resources and Emiratisation sets labor and safety rules. Similarly, Saudi Arabia’s Ministry of Human Resources and Social Development enforces its own codes. Qatar’s Ministry of Labour and Supreme Committee for Delivery & Legacy have specific mandates. Consequently, employers operating across borders must ensure compliance in each jurisdiction.

Non-compliance carries severe penalties. These include hefty fines, project shutdowns, and even imprisonment for negligence. Moreover, companies risk blacklisting from future government tenders. Therefore, maintaining meticulous records of training and certifications is crucial. Regular legal audits help identify gaps before they result in violations.

- Adherence to NFPA 70E standards for electrical workplace safety.

- Local civil defense regulations for site electrical installations.

- Mandatory incident reporting procedures and timelines.

- Requirements for licensed electricians versus helpers or trainees.

- Insurance policy stipulations regarding certified workforce requirements.

Electrical Safety Construction Site Power Best Practices

Implementing electrical safety construction site power best practices reduces incident rates dramatically. First, establish a comprehensive site-specific electrical safety plan. This document should detail all procedures and designate responsible individuals. Furthermore, it must be accessible and understood by all workers, regardless of language.

Daily toolbox talks focused on electrical hazards are essential. These brief meetings reinforce awareness and address current tasks. Additionally, implementing a strict “permit-to-work” system for live electrical work adds a critical control layer. This formal authorization process ensures all hazards are reviewed and mitigated before work begins.

Regular inspection and maintenance of all electrical equipment form another best practice. This includes tools, extension cords, temporary panels, and generators. A color-coding or tagging system can indicate inspection status. Moreover, defective equipment must be removed from service immediately. This proactive approach prevents equipment-related accidents.

- 100% lockout/tagout verification for any work on de-energized systems.

- Use of Ground Fault Circuit Interrupters (GFCIs) for all temporary power.

- Maintaining minimum safe distances from overhead power lines.

- Provision of appropriate voltage-rated gloves, tools, and insulating mats.

- Establishing clearly marked electrical exclusion zones around panels and transformers.

Documentation and Processing Steps

Meticulous documentation underpins a compliant electrical safety program. First, create a master register of all electrical personnel. This register should list each worker’s certifications, expiry dates, and authorized tasks. Furthermore, it must be updated regularly as new workers join or certifications are renewed.

Second, maintain detailed training records for every employee. These records should include the course content, provider, date, and assessment results. Additionally, keep inspection logs for all portable tools and temporary wiring. These logs provide evidence of due diligence during audits or incident investigations.

Third, document all hazard assessments and job safety analyses. This includes pre-task planning for any non-routine electrical work. Moreover, retain copies of all permits to work and lockout/tagout records. A centralized digital system, accessible to site supervisors, streamlines this process. Consequently, it ensures information is available when needed most.

- Digital certification tracking with automated expiry alerts.

- Photographic evidence of corrected electrical hazards.

- Signed acknowledgments from workers receiving safety briefings.

- Audit reports and records of corrective actions taken.

- Equipment testing certificates from calibrated instruments.

Electrical Safety Construction Site Power Implementation Timeline

Developing a realistic electrical safety construction site power implementation timeline is crucial. The pre-mobilization phase is the most critical. During this period, the safety plan is finalized, and key personnel are identified. Additionally, all required certifications for the initial crew must be verified. This phase typically requires 2-4 weeks before site work begins.

Upon mobilization, the first week focuses on site induction. This includes general and electrical-specific safety orientation for all workers. Furthermore, the temporary electrical system installation must be inspected and approved before use. Meanwhile, ongoing training schedules for specialized tasks are established. This ensures a safe foundation for all subsequent activities.

Throughout the project, monthly safety audits and refresher training sessions occur. These activities maintain standards and address emerging risks. Finally, a post-project review captures lessons learned. This review improves the implementation timeline for future projects. Therefore, safety becomes a continuous cycle of planning, action, and improvement.

- Week 1-2: Finalize safety plan and verify crew certifications.

- Week 3-4: Conduct site-wide electrical safety induction.

- Monthly: Perform electrical system audits and refresher training.

- Quarterly: Review incident data and update hazard assessments.

- Project Close: Document lessons learned and archive all safety records.

Common Challenges and Solutions

Employers frequently encounter several challenges in managing electrical safety. A common issue is the prevalence of counterfeit or expired certifications. The solution involves rigorous verification through accredited training centers. Additionally, using a trusted recruitment partner like Allianze HR ensures candidate credentials are authentic from the start.

Another challenge is maintaining safety standards amidst high workforce turnover. This is addressed by standardizing onboarding processes. Furthermore, creating simple, visual work procedures helps bridge language gaps. Investing in train-the-trainer programs also builds internal capacity. Consequently, safety knowledge persists despite personnel changes.

Pressure to meet project deadlines often leads to shortcuts. To counter this, leadership must visibly prioritize safety over speed. Integrating safety compliance into productivity bonuses can align incentives. Moreover, empowering any worker to “stop work” for unsafe conditions without reprisal is vital. This cultural shift is the most powerful solution of all.

- Challenge: Substandard temporary electrical equipment.

Solution: Implement an approved vendor list and mandatory inspection upon delivery. - Challenge: Poor coordination between subcontractors.

Solution: Hold daily coordination meetings with a dedicated electrical safety agenda. - Challenge: Lack of qualified safety supervisors.

Solution: Partner with recruitment firms specializing in professional recruitment resources for safety roles. - Challenge: Complacency with routine low-voltage tasks.

Solution: Rotate hazard identification responsibilities and conduct surprise audits.

Expert Recommendations for Success

To achieve excellence in electrical safety, go beyond basic compliance. First, foster a genuine safety culture where every worker feels responsible. Leadership must model this behavior consistently. Moreover, recognize and reward safe practices publicly. This positive reinforcement strengthens the desired culture more effectively than punishment alone.

Second, leverage technology for enhanced safety management. Drones can inspect overhead lines safely. Thermal imaging cameras detect overloaded circuits before they fail. Additionally, digital checklists on tablets ensure field audits are consistent and recorded. These tools provide data-driven insights for continuous improvement.

Finally, build strategic partnerships. Collaborate with accredited training institutes for customized programs. Partner with recruitment experts to source pre-vetted, certified talent. Furthermore, engage with UAE construction sector employment authorities to stay updated on regulation changes. These partnerships provide external validation and expertise.

- Appoint a dedicated Electrical Safety Officer with authority on site.

- Conduct simulated emergency drills specific to electrical incidents.

- Benchmark your safety performance against World Bank infrastructure development best practices.

- Invest in VR-based training for high-risk, low-frequency scenarios.

- Schedule consultation appointment with HR specialists to audit your workforce’s certification status.

Frequently Asked Questions About Electrical Safety Construction Site Power

What is the core focus of electrical safety construction site power training?

Training focuses on hazard recognition, safe work practices, and emergency response. Specifically, it covers lockout/tagout, PPE use, and working near live components. Furthermore, it addresses both low voltage and high voltage certification requirements. Therefore, workers gain practical skills for real-site dangers.

How do low and high voltage certification requirements differ?

Low voltage certification typically covers systems up to 1000V AC. It emphasizes basic safety and tool use. Conversely, high voltage certification involves systems above 1000V. This requires more advanced training on switching procedures, clearance distances, and specialized PPE. Moreover, renewal periods for high voltage tickets are often shorter due to higher risk.

Who provides accredited electrical safety training in the GCC?

Accredited providers include government-approved institutes, international organizations like NEBOSH, and major contractor in-house academies. Additionally, many World Health Organization workplace standards inform health-focused training content. Employers must verify a provider’s accreditation with the local national authority.

What are the consequences of employing uncertified electrical workers?

Consequences are severe. They include legal liability for accidents, substantial government fines, and project suspension. Moreover, insurance may become void, leaving the company fully liable for damages. Additionally, the firm’s reputation suffers, impacting future tender opportunities. Therefore, rigorous certification checks are a fundamental business protection.

How often should electrical safety refresher training be conducted?

Most certifications require renewal every 2-3 years. However, best practice dictates annual refresher courses. Furthermore, site-specific refreshers should occur after any major incident or change in work process. Additionally, toolbox talks provide weekly reinforcement. This layered approach ensures knowledge remains current and top-of-mind.

Can Allianze HR help source pre-certified electrical safety personnel?

Absolutely. We specialize in recruiting construction professionals with verified credentials. Our screening process includes authenticating training certificates and checking practical experience. Moreover, we understand the specific Saudi Ministry of Labor regulations and other GCC standards. Therefore, we connect you with talent that is both skilled and compliant.

Partner with Allianze HR for Electrical Safety Success

Ensuring electrical safety construction site power compliance is a multifaceted endeavor. It demands strategic planning, continuous training, and meticulous documentation. Furthermore, it requires a workforce that is not only skilled but also properly certified. The stakes are incredibly high, encompassing human life, project viability, and corporate reputation. Therefore, a systematic approach is your strongest safeguard.

Partnering with an expert HR consultancy transforms this challenge into a manageable process. At Allianze HR, we bridge the gap between your project needs and a compliant, safety-ready workforce. We verify certifications, understand regional legal nuances, and provide access to a vast pool of pre-vetted talent. Consequently, you can focus on project delivery with confidence in your team’s safety competence.

Do not leave electrical safety to chance. Proactively build a