Are you confident your facility’s electrical systems meet the stringent and varied regulations across the Gulf Cooperation Council (GCC) nations? Navigating the complex landscape of **electrical safety FM compliance GCC** requirements is a critical challenge for any facility manager operating in the region. Furthermore, failure to comply can result in severe penalties, operational shutdowns, and significant safety risks. Therefore, understanding and implementing a robust compliance framework is not optional—it’s essential for business continuity and workforce protection.

The GCC’s rapid infrastructure development demands world-class facility management (FM) standards. Consequently, electrical safety sits at the core of these standards, governed by a mix of national codes, civil defense regulations, and international benchmarks. Moreover, each country—from the UAE and Saudi Arabia to Qatar and Kuwait—has its own regulatory nuances and enforcement bodies. This regional complexity makes a standardized yet adaptable approach vital for multi-national portfolio managers and local operators alike.

At Allianze HR Consultancy, we understand that compliance starts with competent personnel. Furthermore, our 5+ years of GCC expertise supports clients from 50+ countries in building skilled FM teams. Moreover, our Ministry of External Affairs (India) RA license ensures ethical and compliant recruitment. Therefore, contact our recruitment specialists to secure the certified electricians and FM engineers who will uphold your safety standards.

Understanding GCC Facility Electrical Regulations

GCC nations enforce rigorous electrical safety protocols to protect their substantial infrastructure investments. These regulations are typically anchored in national building codes, which often reference or adapt international standards like the IEC and NFPA. Additionally, civil defense authorities play a crucial enforcement role, conducting regular inspections of commercial and industrial facilities. Their focus extends from proper wiring and earthing to emergency system functionality and fire prevention.

Key regulatory bodies include the UAE’s Civil Defence, Saudi Arabia’s Saudi Standards, Metrology and Quality Organization (SASO), and Qatar’s Ministry of Interior. Each mandates specific certification for electrical workers and periodic inspection regimes. Consequently, facility managers must maintain detailed logs of all maintenance activities, testing certificates, and personnel qualifications. This documentation forms the backbone of any compliance audit.

- UAE: Adherence to UAE Fire and Life Safety Code of Practice, regulated by local Civil Defence departments.

- Saudi Arabia: Compliance with SASO’s Saudi Building Code (SBC), with strict enforcement by municipal authorities.

- Qatar: Qatar Civil Defence (QCD) regulations and Kahramaa (Qatar General Electricity & Water Corporation) standards.

- Kuwait: Kuwait Fire Force (KFF) directives and the Ministry of Electricity & Water (MEW) specifications.

- Oman: Standards set by the Directorate General of Civil Defence and the Authority for Electricity Regulation.

Navigating this multi-layered landscape requires constant vigilance. Therefore, subscribing to updates from relevant authorities and partnering with knowledgeable local experts is non-negotiable for sustained compliance.

Electrical Safety FM Compliance GCC Strategic Overview

Achieving and maintaining **electrical safety FM compliance GCC** standards requires a proactive, strategic framework. This framework must integrate people, processes, and technology. First, it begins with a comprehensive risk assessment of all electrical assets, from main intake rooms to final circuits. Subsequently, this assessment informs a prioritized maintenance schedule aligned with regulatory inspection cycles. Moreover, the strategy must include continuous training for in-house FM staff to keep pace with evolving codes and technologies.

Technology plays an increasingly pivotal role. For instance, Computerized Maintenance Management Systems (CMMS) can track inspection dates, generate work orders, and store compliance certificates digitally. Additionally, IoT-enabled sensors can provide real-time monitoring of electrical parameters, predicting failures before they occur. This predictive approach shifts maintenance from reactive to proactive, directly enhancing safety and compliance posture.

- Develop a centralized compliance register documenting all applicable codes and renewal dates.

- Implement a tiered responsibility matrix defining electrical safety roles from technician to facility director.

- Integrate contractor management protocols to ensure third-party work meets internal and regulatory standards.

- Establish clear key performance indicators (KPIs) for electrical safety, such as PM completion rate and audit findings closure.

- Conduct bi-annual mock audits to identify and rectify gaps before official inspections.

Ultimately, a strategic overview turns compliance from a checklist exercise into a core component of operational excellence and risk management.

Legal Framework and Compliance Standards

The legal foundation for electrical safety in the GCC is robust and enforceable. Primarily, it combines penal codes that assign liability with administrative regulations that specify technical requirements. Facility owners and managers bear direct legal responsibility for any accidents resulting from non-compliance. This can include substantial fines, imprisonment, and revocation of operating licenses. Therefore, understanding this legal exposure is the first step in fostering a culture of safety.

International standards heavily influence local codes. For example, the International Labour Organization (ILO) conventions on occupational safety provide a global baseline. Similarly, the International Facility Management Association (IFMA) offers best practice frameworks adopted by many GCC FM operators. Furthermore, standards like IEC 60364 for electrical installations and NFPA 70E for electrical workplace safety are frequently referenced.

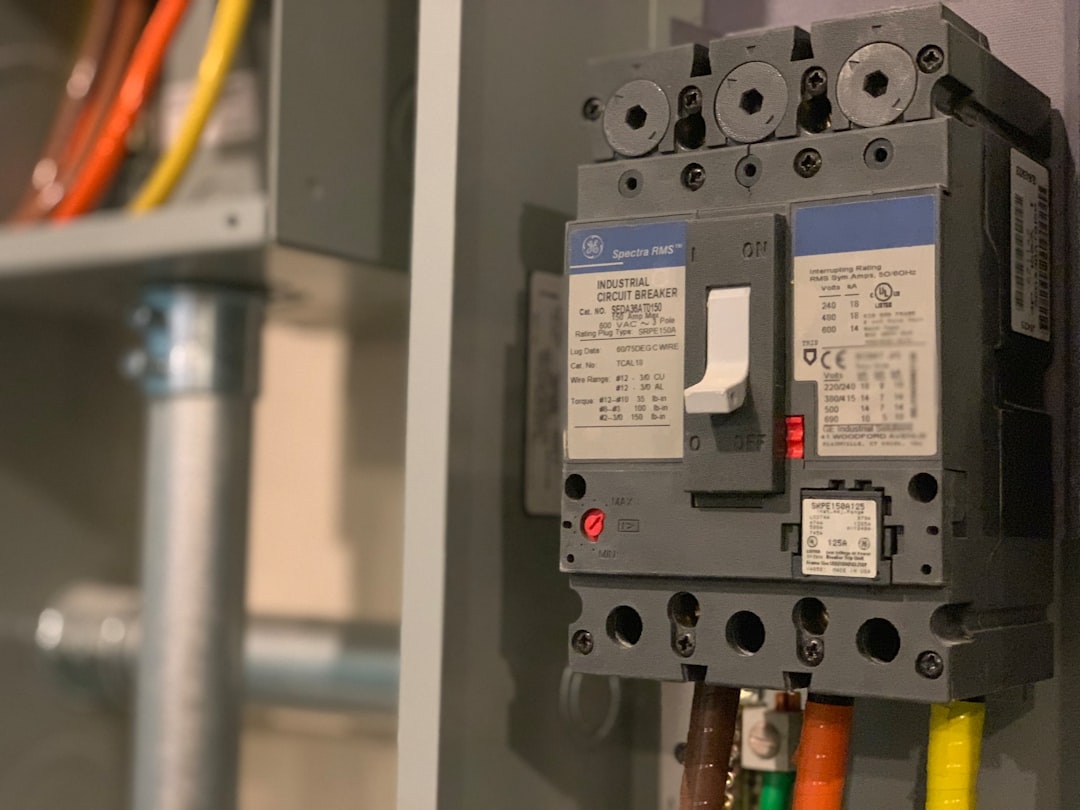

Enforcement is typically carried out through scheduled and surprise inspections. Inspectors will examine electrical panels, emergency lighting, earth fault protection, equipment labeling, and arc flash mitigation. They will also review documentation, including electrical single-line diagrams, load schedules, and maintenance records for critical equipment like generators and UPS systems. Consequently, meticulous record-keeping is as important as the physical condition of the assets.

Staying updated requires active effort. Authorities like the UAE’s regulatory bodies for green buildings periodically update codes to include sustainability and energy efficiency mandates, which intersect with safety. Engaging with professional professional recruitment resources helps you find specialists who are trained on the latest standards.

Electrical Safety FM Compliance GCC Best Practices

Implementing **electrical safety FM compliance GCC** best practices transforms regulatory requirements into daily operational habits. First, establish a Lockout/Tagout (LOTO) program that is strictly enforced for all electrical work. This simple procedure prevents accidental energization and is a universal audit point. Next, ensure all electrical rooms are kept clean, dry, secure, and clearly labeled with appropriate hazard signage. Moreover, access should be restricted to authorized, qualified personnel only.

Regular thermographic (infrared) surveys of electrical connections and panels are a critical predictive tool. These non-invasive scans identify hot spots caused by loose connections or overloads before they cause failures or fires. Additionally, conducting earth resistance testing and insulation resistance testing at intervals specified by the manufacturer or code ensures the integrity of protective systems. Documenting these tests provides tangible proof of due diligence.

- Appoint a dedicated “Authorized Person” for electrical safety with clear authority and accountability.

- Maintain an up-to-date inventory of all electrical assets with their inspection and testing history.

- Use only certified components and equipment that carry GCC conformity marks (like ECAS, G-Mark, QCD).

- Implement a robust permit-to-work system for all hazardous electrical tasks.

- Provide regular, hands-on safety training using scenarios relevant to the specific facility.

These practices, when consistently applied, create a demonstrable safety culture that satisfies inspectors and, more importantly, protects lives and assets. For guidance on building a team capable of upholding these standards, consider to schedule consultation appointment with our experts.

Documentation and Processing Steps

Comprehensive documentation is the evidence trail that proves compliance. The cornerstone document is the Electrical Safety Management Plan (ESMP). This plan outlines policies, procedures, responsibilities, and emergency protocols. Furthermore, it must be a living document, reviewed and updated annually or after any significant incident or change in regulations. Alongside the ESMP, maintain a master file of all electrical drawings, including as-built and updated single-line diagrams.

Processing steps for routine compliance involve cyclical activities. Each month, review completed preventive maintenance (PM) work orders and ensure they are signed off by a competent person. Each quarter, compile test reports from third-party specialists, such as for fire alarm systems or transformer oil analysis. Annually, conduct a full internal audit against the ESMP and all applicable codes, documenting findings and corrective actions in a register.

When facing an official audit, a systematic approach is key. First, gather all required documents in advance, organized by system or area. Second, assign a knowledgeable point of contact to accompany the inspectors. Third, be transparent; if a deficiency is found, present the corrective action plan immediately. This cooperative posture can positively influence the inspector’s assessment. Resources from the World Health Organization on indoor environmental quality can also support documentation for ventilation systems linked to electrical equipment cooling.

Ultimately, well-organized documentation demonstrates control and professionalism. It turns the subjective process of an inspection into an objective review of facts.

Electrical Safety FM Compliance GCC Implementation Timeline

Developing a realistic **electrical safety FM compliance GCC** implementation timeline is crucial for systematic progress. The initial phase, spanning 1-2 months, should focus on gap analysis and planning. This involves a thorough audit of current conditions against regulatory requirements. Subsequently, prioritize findings based on risk—addressing immediate life-safety issues first. Meanwhile, begin drafting or updating the Electrical Safety Management Plan (ESMP).

The execution phase typically extends over 3-6 months. During this period, address high and medium-priority corrective actions. This could include upgrading distribution boards, installing additional emergency lighting, or rectifying earthing systems. Concurrently, roll out training programs for FM staff and contractors. Moreover, implement new processes like the permit-to-work system and digitalize record-keeping where possible. This phase often requires careful budgeting and resource allocation.

- Month 1-2: Gap Analysis, Risk Assessment, ESMP Drafting.

- Month 3-4: Address Critical Findings, Launch Key Training Modules.

- Month 5-6: Implement Process Changes, Begin Digital Documentation.

- Month 7-12: Conduct First Full Internal Audit, Refine Processes, Prepare for External Audit.

- Ongoing: Cyclical Maintenance, Continuous Training, Annual Plan Review.

Finally, the maintenance and review phase is perpetual. Compliance is not a one-time project but an ongoing operational discipline. Regular reviews ensure the program adapts to changes in the facility, its use, and the regulatory landscape, as highlighted in broader World Bank urban development trends affecting infrastructure standards.

Common Challenges and Solutions

Facility managers across the GCC encounter consistent challenges in maintaining electrical safety compliance. A primary issue is the high turnover of skilled technical staff, which leads to loss of institutional knowledge. The solution involves creating standardized operating procedures (SOPs) that are not person-dependent. Additionally, investing in succession planning and competitive compensation packages, facilitated by expert recruiters, retains critical talent.

Another frequent challenge is managing compliance across a portfolio of older and newer buildings. Legacy systems may not meet current codes, and retrofitting can be costly and disruptive. A phased retrofit plan, justified by a risk-based assessment, is the most practical approach. Furthermore, leveraging technologies like wireless monitoring can enhance safety in older buildings without extensive rewiring. Engaging with authorities early to understand acceptable equivalencies is also wise.

Budget constraints often limit proactive maintenance. However, framing electrical safety spending as a risk mitigation investment rather than a cost is essential. Demonstrating the potential financial impact of a single fire or regulatory shutdown can secure necessary funding. Moreover, integrating energy efficiency projects with safety upgrades can improve the return on investment, aligning with initiatives from the ILO’s focus on sustainable workplaces.

Finally, keeping abreast of regulatory changes is a constant task. Subscribing to updates from local civil defense, joining industry associations, and attending GCC-specific FM conferences are effective strategies to stay informed.

Expert Recommendations for Success

To ensure long-term success in electrical safety compliance, adopt a holistic and integrated approach. First, leadership commitment is non-negotiable. Safety culture must be championed from the top, with adequate resources and authority granted to the FM team. Second, view your electrical infrastructure data as a strategic asset. Analyze failure trends and maintenance costs to make informed, data-driven decisions about upgrades and replacements.

Third, foster strong relationships with local authorities. Proactive communication with civil defense and utility providers can provide valuable insights into enforcement trends and upcoming regulation changes. Fourth, never compromise on the quality of materials or the competency of personnel. Using substandard components or unqualified contractors is a false economy that exponentially increases risk.

Consider benchmarking your program against international frameworks beyond basic compliance. Standards like ISO 41001 for Facility Management provide a structured management system approach. Additionally, explore certifications like LEED or WELL that incorporate stringent electrical and environmental quality metrics, as referenced in WHO guidelines. These can differentiate your facility in the market.

Ultimately, the most successful organizations embed electrical safety into their core values. They recognize that a safe facility is a productive, efficient, and reputable one.

Frequently Asked Questions About Electrical Safety FM Compliance GCC

What is the primary standard for electrical safety FM compliance GCC?

There is no single standard. Compliance requires adhering to each GCC country’s national building code and civil defense regulations, which often reference IEC and NFPA standards. Furthermore, facility-specific requirements depend on building type and use.

How often should electrical installations be professionally inspected?

Most GCC civil defense regulations mandate a comprehensive inspection and testing certificate every 1-3 years for commercial facilities. Additionally, internal preventive maintenance and thermographic surveys should occur more frequently, typically every 6-12 months.

Who is legally responsible for electrical safety in a facility?

Ultimate legal responsibility rests with the facility owner or tenant (the occupier). However, this duty is often delegated to the facility manager or a designated “Responsible Person.” Consequently, clear contracts and management plans must define these roles and liabilities.

What are the consequences of non-compliance?

Penalties can be severe, including substantial fines, operational suspension, imprisonment for responsible individuals, and invalidation of insurance claims. Moreover, reputational damage can have long-term business consequences.

Can international electrical standards be used in the GCC?

International standards (IEC, NFPA, BS) are widely respected and often form the technical basis of local codes. However, the final authority is always the national regulation. Therefore, designs and installations must be approved by the local authority having jurisdiction (AHJ).