How can your facility management (FM) operations in the GCC ensure absolute safety when storing and handling hazardous chemicals? Furthermore, the region’s rapid industrial growth demands rigorous chemical management protocols. Consequently, improper storage poses severe risks to personnel, assets, and the environment. Therefore, mastering chemical storage FM hazardous materials procedures is a critical compliance and safety imperative for all employers.

The GCC’s construction, manufacturing, and hospitality sectors rely on various chemicals daily. Moreover, extreme temperatures in the region amplify chemical volatility risks. Additionally, stringent regulations from civil defense and environmental authorities govern storage practices. Hence, a systematic approach to hazardous material handling is non-negotiable for operational continuity and legal adherence.

At Allianze HR Consultancy, we’ve successfully placed 10,000+ professionals across UAE, Saudi Arabia, Qatar, and Kuwait. Furthermore, our 5+ years of GCC expertise supports clients from 50+ countries in building safe, compliant teams. Moreover, our Ministry of External Affairs (India) RA license ensures all recruitment meets the highest standards. Therefore, contact our recruitment specialists for expert guidance on staffing your FM safety operations.

Understanding GCC Hazardous Material Requirements

GCC nations enforce specific regulations for dangerous goods management. For example, UAE Federal Law No. 24 and Saudi Arabia’s SBC 601 provide clear frameworks. Additionally, local civil defense departments conduct regular facility inspections. Consequently, non-compliance can result in heavy fines, operational shutdowns, or legal prosecution.

Furthermore, classification of chemicals is the foundational step. Specifically, materials are categorized by flammability, toxicity, corrosivity, and reactivity. Moreover, Safety Data Sheets (SDS) must be available for every substance. Therefore, FM teams must be trained to interpret SDS information correctly. This ensures proper segregation and storage protocols are followed meticulously.

Key regional considerations include climate adaptation. Specifically, storage areas require temperature and humidity control. Additionally, ventilation systems must prevent fume accumulation. Also, spill containment measures are mandatory for all storage cabinets and rooms. Finally, emergency eyewash stations and showers must be accessible within 10 seconds.

- Adhere to UAE Civil Defense Code for chemical storage.

- Classify all materials using GHS (Globally Harmonized System) standards.

- Maintain accessible, multilingual Safety Data Sheets (SDS).

- Implement climate-controlled storage for temperature-sensitive chemicals.

- Designate specific zones for incompatible hazardous materials.

Chemical Storage FM Hazardous Materials Strategic Overview

A strategic overview of chemical storage FM hazardous materials begins with risk assessment. First, identify all chemicals present and their associated hazards. Next, evaluate quantities, usage frequency, and storage conditions. Then, develop control measures to mitigate identified risks. Finally, establish continuous monitoring and review procedures.

Moreover, the hierarchy of controls should guide your strategy. Primarily, aim to eliminate or substitute hazardous chemicals with safer alternatives. Where substitution isn’t possible, implement engineering controls like ventilated storage cabinets. Subsequently, use administrative controls such as strict handling procedures and permits. Additionally, personal protective equipment (PPE) serves as the final defense layer.

Furthermore, inventory management is a crucial strategic component. Specifically, implement a first-in, first-out (FIFO) system to prevent material degradation. Also, maintain accurate real-time records of all chemical stocks. Consequently, this prevents over-purchasing and reduces storage volumes. Therefore, it directly lowers overall facility risk profiles.

- Conduct a comprehensive chemical inventory and risk assessment.

- Apply the hierarchy of controls (elimination, substitution, engineering).

- Implement a digital chemical tracking and FIFO inventory system.

- Develop clear standard operating procedures (SOPs) for all activities.

- Establish regular audit schedules with corrective action tracking.

Legal Framework and Compliance Standards

Navigating the legal landscape is essential for GCC facility managers. International standards like NFPA 30 and ISO 14001 provide strong foundations. Additionally, local regulations add specific layers of compliance. For instance, the International Labour Organization workplace safety conventions influence GCC labor laws. Therefore, a multi-tiered compliance approach is necessary.

Furthermore, documentation proves regulatory adherence during inspections. Specifically, maintain records of employee training, SDS, risk assessments, and inspection reports. Moreover, permits are often required for storing certain quantities or types of chemicals. Consequently, understanding permit application processes with local authorities is critical. This prevents unexpected operational disruptions.

Additionally, International Facility Management Association guidelines offer best practice frameworks. Also, UAE green building regulations like Estidama may influence storage practices. Similarly, World Health Organization indoor air quality guidelines impact ventilation requirements. Finally, World Bank urban development reports often highlight regional safety priorities.

- Align practices with NFPA, ISO, and local civil defense codes.

- Secure and renew all necessary storage and handling permits.

- Maintain a complete and organized compliance documentation file.

- Schedule pre-inspection audits to identify and rectify gaps.

- Appoint a dedicated compliance officer for hazardous materials.

Chemical Storage FM Hazardous Materials Best Practices

Implementing best practices for chemical storage FM hazardous materials ensures daily safety. First, segregation by hazard class prevents dangerous reactions. For example, store oxidizers away from flammables and acids away from bases. Moreover, use compatible, labeled, and undamaged containers for all substances. Also, ensure containers remain tightly closed when not in use.

Furthermore, storage area design requires careful planning. Specifically, use dedicated, well-ventilated rooms with fire-rated construction. Additionally, install spill containment bunds that can hold 110% of the largest container’s volume. Consequently, secondary containment prevents environmental contamination. Therefore, it is a fundamental requirement in all GCC jurisdictions.

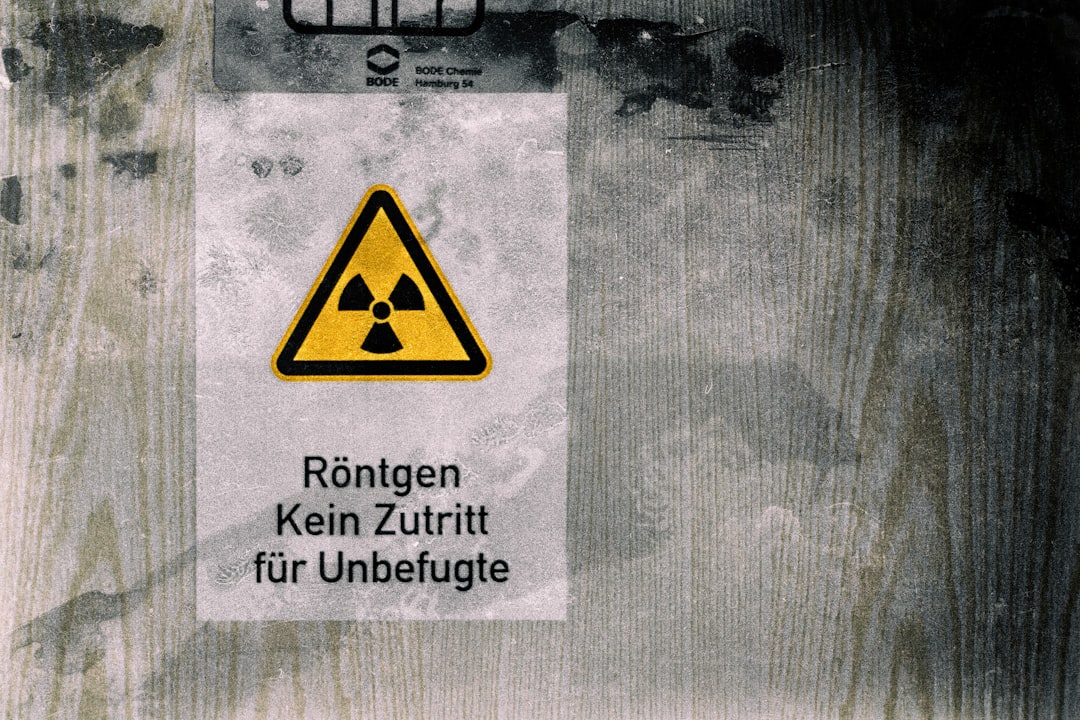

Moreover, signage and labeling provide critical visual communication. Clearly mark storage areas with hazard symbols and warning signs. Also, label all containers with content name, hazard pictograms, and risk phrases. Subsequently, ensure all signage is in both Arabic and English. This meets regional regulatory requirements and enhances worker understanding.

- Segregate chemicals by hazard class using a verified compatibility chart.

- Utilize approved safety cabinets and storage rooms with proper ventilation.

- Implement robust secondary containment for all storage locations.

- Apply clear, bilingual labeling on all containers and storage zones.

- Enforce strict “no food or drink” policies in chemical storage areas.

Documentation and Processing Steps

Effective chemical management relies on meticulous documentation. The Safety Data Sheet (SDS) is the cornerstone document for every chemical. Furthermore, employers must ensure SDSs are readily accessible to all employees. Additionally, chemical inventories must be updated with each new purchase or disposal. Consequently, accurate records enable proper risk assessment and emergency response.

Moreover, processing steps for receiving chemicals are vital. First, inspect incoming containers for leaks or damage before accepting delivery. Next, verify that the label matches the SDS and purchase order. Then, document the receipt in the central inventory system. Finally, transport the chemical immediately to its designated storage location using appropriate equipment.

Additionally, disposal procedures require strict documentation. Track chemical waste from generation to final disposal using waste manifests. Furthermore, only use licensed and approved waste contractors for removal. Also, maintain certificates of disposal for regulatory audits. Therefore, proper documentation closes the lifecycle management loop safely and legally.

- Maintain an accessible, centralized SDS library (digital or physical).

- Update the chemical inventory log with every transaction.

- Follow a formal checklist for receiving and inspecting chemical deliveries.

- Document all employee training and competency assessments.

- Keep detailed waste disposal manifests and contractor certificates.

Chemical Storage FM Hazardous Materials Implementation Timeline

Developing a realistic timeline for chemical storage FM hazardous materials program rollout is crucial. Phase One (Weeks 1-2) involves initial assessment and planning. Specifically, form a project team and conduct a full chemical inventory. Moreover, identify immediate high-risk issues for urgent remediation.

Phase Two (Weeks 3-6) focuses on system design and procurement. During this period, design storage layouts and order necessary equipment like cabinets and spill kits. Additionally, draft all required SOPs and training materials. Consequently, this phase establishes the program’s physical and procedural foundations.

Phase Three (Weeks 7-10) entails implementation and training. Execute the storage area reorganization according to segregation rules. Furthermore, conduct comprehensive training for all affected staff. Finally, Phase Four (Week 11 onward) is for auditing and continuous improvement. Schedule the first internal audit and establish a quarterly review cycle.

- Week 1-2: Project initiation, team formation, and baseline inventory.

- Week 3-6: Design storage solutions, procure equipment, draft SOPs.

- Week 7-10: Physically reorganize storage, conduct full staff training.

- Week 11: Perform first internal audit and management review.

- Ongoing: Quarterly audits, annual refresher training, and system updates.

Common Challenges and Solutions

Facilities across the GCC encounter similar hazardous material challenges. A frequent issue is space constraints leading to improper segregation. The solution involves vertical storage with approved shelving and clear zoning. Additionally, consolidating rarely used chemicals to a central warehouse can free up space.

Another common challenge is high staff turnover affecting competency. Implement a robust onboarding program with mandatory chemical safety training. Moreover, use visual guides and multilingual instructions to bridge language gaps. Consequently, consistent training ensures safety knowledge persists despite workforce changes.

Furthermore, managing chemical waste streams poses difficulties. Partner with reputable waste management vendors early in the planning process. Also, implement miniaturization or micro-chemistry techniques to reduce waste generation. Therefore, proactive waste management simplifies compliance and reduces costs.

- Challenge: Limited storage space. Solution: Optimize vertical space and centralize bulk storage.

- Challenge: Staff turnover. Solution: Standardized onboarding and visual SOPs.

- Challenge: Complex waste disposal. Solution: Early vendor partnership and waste minimization.

- Challenge: Regulatory changes. Solution: Designate a compliance lead to monitor updates.

- Challenge: Emergency preparedness. Solution: Regular, realistic drills and equipment checks.

Expert Recommendations for Success

For long-term success, integrate chemical safety into your corporate culture. Leadership must visibly champion safety protocols and provide necessary resources. Furthermore, empower employees to report near-misses and unsafe conditions without fear. Consequently, a proactive safety culture prevents incidents before they occur.

Moreover, leverage technology for enhanced management. Use barcode or RFID systems for accurate chemical tracking. Additionally, digital SDS management platforms ensure instant access. Also, consider sensors for continuous monitoring of storage area temperature and air quality. Therefore, technology provides real-time data for informed decision-making.

Finally, engage with professional recruitment resources to build a competent team. Hiring qualified FM professionals with specific hazardous material experience is invaluable. Additionally, schedule consultation appointment with experts to review your plans. Continuous professional development for your team ensures skills remain current with evolving standards.

- Foster a top-down safety culture with leadership accountability.

- Invest in digital inventory and SDS management systems.

- Conduct joint training sessions with local civil defense authorities.

- Perform scenario-based emergency drills bi-annually.

- Partner with specialized recruiters to source certified hazardous material handlers.

Frequently Asked Questions About Chemical Storage FM Hazardous Materials

What is the timeline for chemical storage FM hazardous materials program implementation?

A full implementation typically takes 10-12 weeks. Furthermore, the timeline includes assessment, planning, procurement, and training phases. Therefore, consult our specialists for a customized project plan.

What documentation is required for hazardous material compliance audits?

Required documents include Safety Data Sheets (SDS), chemical inventory lists, risk assessments, training records, waste manifests, and inspection reports. Additionally, permits and emergency response plans are mandatory for auditor review.

How should incompatible chemicals be segregated in storage?

Use separate storage cabinets with adequate distance between them. Alternatively, employ secondary containment within a single cabinet. Moreover, always consult a chemical compatibility chart. Physical barriers prevent accidental mixing during leaks or spills.

What are the key elements of effective staff training for chemical handling?

Training must cover hazard identification, SDS interpretation, proper PPE use, safe handling techniques, spill response, and emergency procedures. Additionally, hands-on drills and annual refreshers are crucial for competency retention.

Does Allianze HR recruit FM staff with hazardous material certification?

Yes. We specialize in sourcing qualified facilities management professionals. Furthermore, our network includes candidates with specific certifications in NEBOSH, IOSH, and hazardous material handling. Moreover, we verify all credentials during our screening process.

What is the first step in improving our chemical storage safety?

Conduct a complete chemical inventory and risk assessment. This baseline evaluation identifies immediate hazards and compliance gaps. Subsequently, it informs the development of a prioritized action plan for systematic improvement.

Partner with Allianze HR for Hazardous Material Management Success

Mastering chemical storage FM hazardous materials is a complex but essential responsibility for GCC employers. This guide has outlined the strategic, compliance, and practical steps required for safety. Furthermore, proper management protects your workforce, ensures regulatory compliance, and safeguards your corporate reputation. Therefore, viewing chemical safety as an investment, not a cost, is crucial for sustainable operations.

Moreover, your team’s competency directly impacts program effectiveness. Sourcing and retaining staff with the right technical skills and safety mindset is paramount. Additionally, continuous training and a strong safety culture are the bedrocks of incident prevention. Consequently, partnering with an expert recruitment firm provides a significant strategic advantage.

Allianze HR Consultancy delivers that advantage. We connect you with pre-vetted FM professionals experienced in hazardous material protocols. Furthermore, our deep understanding of GCC labor markets and compliance landscapes adds immense value. Let us help you build a team that prioritizes safety and operational excellence. Take the next step toward a safer facility today by reaching out to our experts for a