Are you struggling with escalating utility costs across your GCC operations? Furthermore, energy represents a significant and controllable operational expense for businesses in the region. Therefore, mastering energy efficiency and power consumption reduction is no longer optional. It is a strategic imperative for cost control and sustainability. This guide provides a comprehensive framework for energy efficiency power consumption management tailored to the Gulf market.

GCC nations are actively pursuing ambitious sustainability goals, such as Saudi Arabia’s Vision 2030 and the UAE’s Energy Strategy 2050. Consequently, commercial and industrial energy consumption faces increasing scrutiny. Moreover, the region’s extreme climate makes cooling and process loads substantial. Implementing effective energy management directly impacts your bottom line and corporate reputation. Additionally, it ensures compliance with evolving regional regulations.

At Allianze HR Consultancy, we recognize that operational excellence extends beyond staffing. Efficient facility management relies on skilled personnel implementing best practices. Furthermore, our 5+ years of GCC expertise supports clients from 50+ countries in building optimized teams. Moreover, our Ministry of External Affairs (India) RA license ensures compliance in all deployments. Therefore, contact our recruitment specialists for expert guidance on staffing your sustainability initiatives.

Understanding GCC Operational Energy Challenges

Businesses in the Gulf face unique energy consumption drivers. First, extreme ambient temperatures necessitate intensive air conditioning for up to nine months annually. Second, older building stock often lacks modern insulation and efficient systems. Third, historically subsidized energy prices have reduced the urgency for conservation investments. However, this landscape is changing rapidly with economic diversification efforts.

Additionally, industrial and construction sectors are major power consumers. For example, data centers, manufacturing plants, and large hospitality venues operate 24/7. Consequently, even minor efficiency gains yield substantial financial savings. Furthermore, regional governments are introducing tariffs and regulations to incentivize reduction. Therefore, proactive energy management becomes a competitive advantage.

Key consumption areas include HVAC (Heating, Ventilation, and Air Conditioning), lighting, water heating, and process equipment. Moreover, office equipment and server rooms contribute significantly to baseload. Identifying your specific load profile is the essential first step. Subsequently, targeted strategies can be developed for maximum impact and cost control.

- HVAC systems account for 40-60% of typical commercial building energy use.

- Lighting represents 15-25% of electricity consumption in office environments.

- Process loads in manufacturing vary but offer high savings potential.

- Standby power from idle equipment can constitute 5-10% of total use.

- Water heating and pumping are significant in hospitality and residential sectors.

Energy Efficiency Power Consumption Strategic Overview

Developing a strategic plan for energy efficiency power consumption management requires a structured approach. First, conduct a comprehensive energy audit to establish a baseline. This audit quantifies consumption patterns and identifies waste. Second, set clear, measurable reduction targets aligned with business goals. Third, prioritize actions based on cost, savings potential, and implementation complexity.

Furthermore, engagement from leadership and staff is critical for success. Therefore, establish a cross-functional energy management team. This team should include facilities, finance, and operations personnel. Moreover, assign clear accountability for meeting reduction targets. Additionally, integrate energy performance into regular management reviews. Consequently, efficiency becomes embedded in organizational culture.

A successful strategy balances technology, behavior, and process. For instance, upgrading equipment must be paired with operational training. Meanwhile, monitoring systems provide the data needed for continuous improvement. Hence, a holistic view ensures sustained results. Finally, consider leveraging external expertise for audits and implementation support.

- Establish a baseline with sub-metering for major energy-consuming systems.

- Set SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound).

- Create an investment plan focusing on quick wins and long-term projects.

- Implement a communication plan to engage all employees in conservation.

- Regularly benchmark performance against industry standards and peers.

Legal Framework and Compliance Standards

GCC countries are implementing robust regulatory frameworks for energy conservation. For example, the UAE has Estidama Pearl Rating System and Dubai’s Green Building Regulations. Similarly, Saudi Arabia’s Saudi Energy Efficiency Center (SEEC) sets mandatory standards. Moreover, Qatar’s Global Sustainability Assessment System (GSAS) applies to major projects. Compliance is increasingly tied to building permits and operational licenses.

Furthermore, international standards provide excellent guidance. The ISO 50001 Energy Management System standard offers a recognized framework. Additionally, International Labour Organization guidelines link efficient workplaces to worker wellbeing. Adopting these standards demonstrates corporate responsibility. It also future-proofs operations against tightening local regulations.

Understanding local utility regulations is also crucial. Some Emirates offer incentives or rebates for efficiency upgrades. Conversely, penalties may apply for exceeding certain consumption thresholds. Therefore, staying informed is a key component of cost control. Regularly consult official sources like the UAE green building regulations portal for updates.

- Adhere to local building codes mandating insulation values and equipment efficiency.

- Follow appliance and motor Minimum Energy Performance Standards (MEPS).

- Prepare for mandatory energy audits and public disclosure requirements.

- Utilize government incentive programs for retrofits and renewable energy.

- Ensure compliance with WHO indoor air quality standards when optimizing HVAC.

Energy Efficiency Power Consumption Best Practices

Implementing proven best practices is the core of effective energy efficiency power consumption reduction. Start with operational and behavioral changes that require little capital. For example, establish temperature set-point policies for HVAC systems. Furthermore, implement strict lighting schedules and “switch-off” campaigns. Additionally, optimize equipment run-times and maintenance schedules to prevent energy waste.

Moreover, preventive maintenance is a low-cost, high-impact practice. Clean filters, coils, and solar panels regularly. Also, calibrate controls and fix steam leaks promptly. Consequently, systems operate at peak designed efficiency. Meanwhile, employee training ensures that staff understand their role. For instance, training can cover proper equipment use and reporting of energy faults.

For capital projects, focus on high-return areas. LED lighting retrofits typically have payback periods under two years. Similarly, variable speed drives (VSDs) on pumps and fans can reduce motor energy use by 30-50%. Furthermore, building automation systems (BAS) optimize entire building performance. Therefore, a phased investment approach manages cash flow while delivering savings.

- Optimize HVAC set points: 24-26°C for cooling in summer, 20-22°C for heating in winter.

- Install occupancy and daylight sensors for automatic lighting control.

- Implement power management settings on all computers and office equipment.

- Use energy-efficient water heating systems, like heat pumps or solar thermal.

- Improve building envelope with window films, insulation, and shading devices.

Equipment Selection and Usage Monitoring

Strategic equipment selection is fundamental for long-term energy savings. First, always specify high-efficiency models, even at a premium cost. Lifecycle cost analysis, not just purchase price, should guide decisions. Second, right-size equipment to match the actual load. Oversized HVAC units, for example, cycle inefficiently and increase wear. Third, consider smart equipment with built-in energy management features.

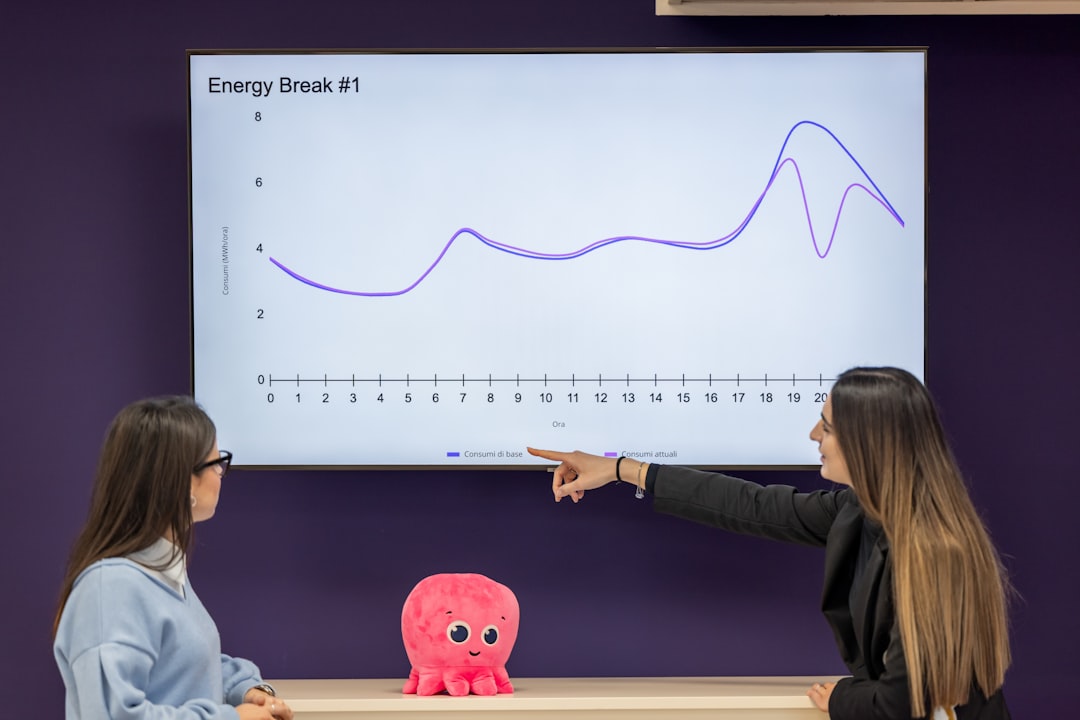

Furthermore, usage monitoring transforms data into actionable insights. Sub-metering critical systems like HVAC, lighting, and process lines is essential. Moreover, Energy Management Information Systems (EMIS) collect and analyze this data. Therefore, you can identify anomalies, track savings, and verify project ROI. Additionally, real-time dashboards raise awareness and drive behavioral change.

Monitoring also supports predictive maintenance. For instance, rising energy consumption for a chiller may indicate fouled tubes. Addressing this early prevents higher costs and potential failure. Consequently, operational reliability improves alongside efficiency. Resources from the International Facility Management Association offer valuable guidance on these technologies.

- Select equipment with best-in-class efficiency ratings (e.g., SEER, EER, COP).

- Implement sub-metering for at least 80% of your total energy consumption.

- Use cloud-based analytics platforms to benchmark and identify waste.

- Establish key performance indicators (KPIs) like kWh per square meter or unit produced.

- Integrate monitoring data with maintenance management software for proactive alerts.

Energy Efficiency Power Consumption Implementation Timeline

Executing a successful energy efficiency power consumption program follows a logical timeline. Phase One (Weeks 1-4) involves assessment and planning. Conduct the initial audit and secure management commitment. Phase Two (Months 2-3) focuses on low-cost operational measures. Implement behavior change programs and basic maintenance improvements.

Phase Three (Months 4-12) entails deeper investment and monitoring. Execute quick-payback retrofits like lighting upgrades. Furthermore, install sub-metering and monitoring systems during this period. Phase Four (Year 2 onward) involves continuous optimization and major projects. Pursue capital-intensive upgrades like chiller replacement or building envelope improvements.

Moreover, this timeline is iterative. Monitoring data from Phase Three informs projects in Phase Four. Therefore, the process becomes a cycle of measurement and improvement. Meanwhile, regular reporting keeps stakeholders engaged. Annual reviews ensure the program adapts to new technologies and business needs. Consequently, energy performance improves steadily over time.

- Month 1: Energy audit completion and baseline establishment.

- Months 2-3: Launch employee engagement and fix obvious operational waste.

- Months 4-6: Complete lighting and control system retrofits; install key meters.

- Months 7-12: Analyze monitoring data; plan next-phase capital projects.

- Year 2+: Implement major system upgrades; pursue certification (e.g., ISO 50001).

Common Challenges and Practical Solutions

Employers often face similar obstacles when pursuing energy reduction. First, securing upfront capital for improvements can be difficult. Solution: Explore Energy Performance Contracting (EPC) where a service provider finances upgrades. Savings are used to repay the investment. Second, lack of internal expertise hinders progress. Solution: Partner with qualified Energy Service Companies (ESCOs) or consult professional recruitment resources to hire skilled facility managers.

Third, employee resistance to change can undermine behavioral initiatives. Solution: Create incentive programs and communicate benefits clearly. Furthermore, involve staff in identifying savings opportunities. Fourth, measuring and verifying savings poses a technical challenge. Solution: Use International Performance Measurement and Verification Protocol (IPMVP) standards. This provides a credible framework for quantifying results.

Finally, keeping pace with technology is daunting. Solution: Focus on foundational best practices first. Then, adopt proven technologies with strong track records. Additionally, network with peers through industry groups. Learning from others’ experiences accelerates your journey. Reports from the World Bank urban development program can provide macro-level insights.

- Challenge: Split incentives (owner pays for upgrade, tenant gets savings). Solution: Green lease agreements.

- Challenge: Dispersed operations across multiple sites. Solution: Centralized monitoring with site-specific targets.

- Challenge: Proving business case for efficiency. Solution: Use case studies and calculate full lifecycle costs.

- Challenge: Maintaining momentum after initial projects. Solution: Integrate energy KPIs into regular business reviews.

- Challenge: Navigating regional regulations. Solution: Engage local sustainability consultants for guidance.

Expert Recommendations for Sustained Success

For lasting results, integrate energy management into your core business processes. First, appoint a dedicated Energy Manager with authority to implement changes. Second, make energy efficiency a key criterion in all procurement decisions. Third, pursue formal certification like ISO 50001 to structure your program. This framework ensures continuous improvement beyond one-off projects.

Furthermore, consider the intersection of energy, water, and waste. An integrated resource management approach often reveals synergistic savings. For example, reducing water consumption also saves the energy used for pumping and heating. Moreover, explore on-site renewable energy generation, such as solar PV. Declining technology costs make solar a viable option for reducing grid dependence in the GCC.

Finally, view efficiency as a component of talent attraction and retention. Modern employees value working for environmentally responsible companies. Therefore, promoting your sustainability efforts enhances employer branding. It also aligns with the strategic visions of host nations. For tailored support in building your operational excellence team, schedule consultation appointment with our experts.

- Treat energy as a manageable cost center, not a fixed overhead.

- Foster a culture of conservation through recognition and rewards.

- Leverage data analytics for decision-making, not just reporting.

- Engage with utility providers to understand tariff structures and demand charges.

- Benchmark performance annually against industry standards and regional best practices.

Frequently Asked Questions About Energy Efficiency Power Consumption

What is the first step in energy efficiency power consumption management?

The essential first step is conducting a detailed energy audit. This assessment establishes your consumption baseline. Furthermore, it identifies the largest areas of waste and savings potential. Therefore, you can prioritize actions effectively for maximum cost control.

How can I fund energy-saving upgrades with limited capital?

Energy Performance Contracting (EPC) is a popular solution. An ESCO finances and implements upgrades. Subsequently, the cost is repaid from the achieved energy savings. Additionally, many GCC governments offer rebate programs for efficient equipment and solar installations.

What are the fastest payback energy reduction measures?

Operational and behavioral measures have immediate payback. These include optimizing HVAC set-points and scheduling. Moreover, LED lighting retrofits typically pay back in 1-3 years. Additionally, preventive maintenance on existing systems improves efficiency at minimal cost.

Why is monitoring usage as important as upgrading equipment?

Monitoring provides the data to verify savings and detect problems. Without measurement, you cannot manage performance effectively. Furthermore, it helps identify operational inefficiencies that equipment upgrades alone cannot fix. Consequently, it ensures continuous improvement.

How do GCC regulations impact commercial energy consumption?

Regulations are becoming increasingly stringent. New buildings must comply with green codes like Estidama or GSAS. Moreover, existing buildings may face mandatory audits and retrofit requirements. Therefore, proactive management ensures compliance and avoids potential penalties.